The Purpose of The Tablet Counting Machine

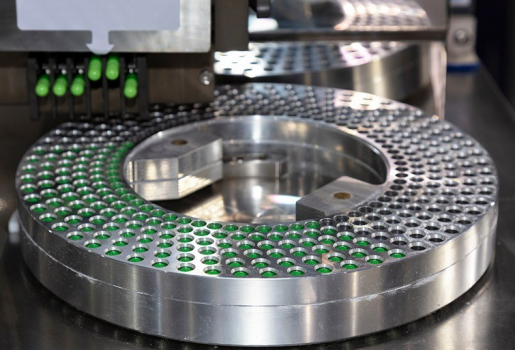

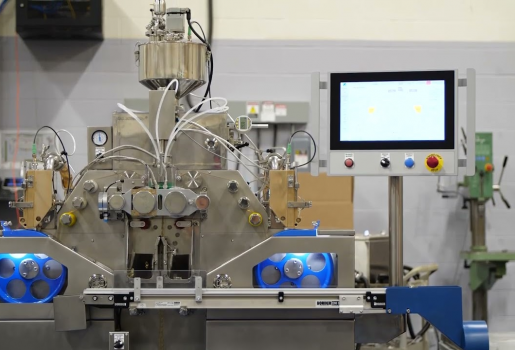

The counting machine can count both tablets and capsules! Truly do one machine dual use! It is mainly used for small-scale quantitative packaging of capsules and tablets, and is very suitable for small and medium-sized batch experiments and production in pharmaceutical factories, scientific research institutions and laboratories.

At present, although the application range of the number of grain machine is very wide, many people do not know how to operate correctly, and many details in the operation process are not clear. Today I will give you a detailed introduction. The correct operation is divided into pre-operation, post-operation and post-operation. Before operation, the user should check whether the glass turntable and the vibrator have stopped; Check the glass turntable and discharge chute for other debris; Adjust the particle opening size, adjust the tracker; Adjust riser height to lock positioner. After that, turn on the power and set the quantity parameters required for the production process. Note that the turntable and vibrator start slowly and check that the particles slide smoothly. If all the requirements are met, then it is ready to operate.

When running, the emission of vibration particles should match the speed of the rotating table in operation, and it should be noted that the disk surface should not accumulate any material, so as not to block the track. If there is too much material, it is easy to overlap or block in the tracker, and the count is not accurate. The control signal preset of the power outage circuit is closed by the switching diode and relay, the counting input is cut off, the counting input is grounded, and the feeding count is stopped.

In addition, the user should pay attention to the operation of the counting machine, otherwise it may not work properly; When lifting the machine, do not hang the machine on the counter board, otherwise the counter board will be loose and damaged; The buckle on the counter must be adjusted to the right height. The bottom edge should be kept at an appropriate distance from the particle head, too low or too high will damage the particle. The material particles must be completely locked and of the same length. There must be no unqualified particles, otherwise it will affect the quantity and quality of the particles.

The purchase of high-quality counting machine is the basic condition for users to ensure the quality of counting. However, in the process of use, due to improper operation or error, some users will use directly, or do not pay attention to details during the operation. The counting equipment must be operated correctly, and some details must be paid attention to in the operation process in order to achieve a good counting effect and ensure high-quality production.