SPM Softgel Encapsulation Machine Introduction

Soft Capsule Machine Introduction

The soft capsule machine is a crucial piece of equipment in the pharmaceutical and healthcare industry. It is used to produce soft capsules, which are becoming increasingly popular as a drug delivery system due to their numerous advantages. In this article, we will provide a comprehensive introduction to soft capsule machines, including their types, operation, features, and benefits.

Types of Soft Capsule Machines

oft capsule machines can be classified based on their size, production capacity, and features. The two main types of soft capsule machines are as follows:

Tabletop Machines: These machines are small and compact, ideal for small-scale production. They are typically manually operated and have a low to medium production capacity. Tabletop machines are cost-effective and suitable for use in small pharmacies or laboratories.

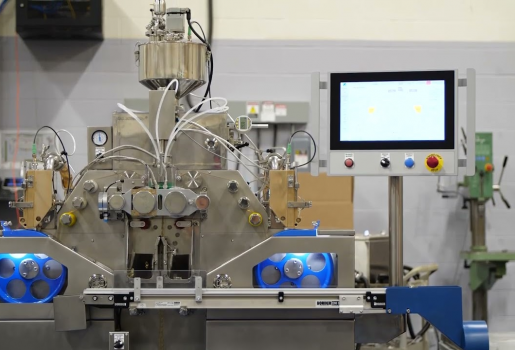

Industrial Machines: Industrial machines are larger and more sophisticated, designed for high-volume production. These machines are typically semi-automatic or fully automatic, reducing the need for manual intervention. They offer a high production capacity, efficient drug delivery, and consistent quality. Industrial machines are commonly used in large-scale pharmaceutical manufacturing facilities.

Operation of Soft Capsule Machines

Soft capsule machines operate based on a patented technology that uses soft gelatin as a carrier for encapsulating active ingredients. The process involves several steps:

The machine mixes the active ingredients with a solution of gelatin and water, creating a viscous material.

The viscous material is fed into the machine through a hopper or pump.

The machine then forms the material into soft gelatin capsules using a molding process.

The formed capsules are conveyed to a drying chamber where they are dried to ensure their stability and longevity.

Finally, the dried capsules are collected and packaged for further use.

Features of Soft Capsule Machines

Soft capsule machines are designed with advanced fea.