SPM Rotary Tablet Press Working Principle And Application

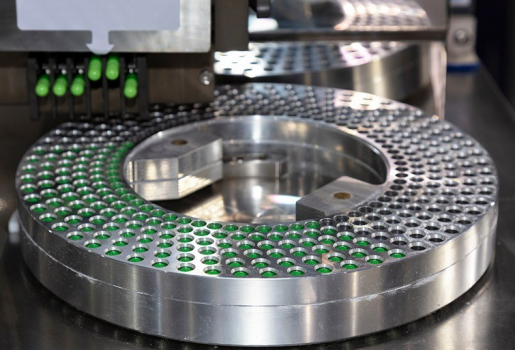

Tablet presses, or rotary tablet presses, play a vital role in the pharmaceutical industry and are one of the core equipment in the pharmaceutical process. Its main working principle is to compress granular or powdered drugs into tablets of a fixed shape and size through a rotating tableting wheel. Let’s take a closer look at the applications of rotary tablet presses and their importance in the pharmaceutical field.

1.Working principle of rotary tablet press

The working principle of a rotary tablet press is relatively simple but efficient. Drug granules or powder are filled into a mold and then compressed into tablets by the pressure of a tableting wheel. This process is continuous, so the tablet press can produce tablets at high speeds and in large quantities.

2.Application of rotary tablet press

- Pharmaceutical industry: Rotary tablet presses are most widely used in the pharmaceutical industry. Whether it is a large pharmaceutical company or a small pharmaceutical factory, they need to use rotary tablet presses to produce various types of tablets, such as oral tablets, lozenges, sugar-coated tablets, etc.

- Health care products industry: The health care products industry is also an important application field of rotary tablet presses. Many health products, such as vitamin tablets, calcium tablets, etc., need to be produced through tablet presses.

- Veterinary drug industry: Rotary tablet presses are also often used in the production of veterinary drugs. Due to the large demand for veterinary drugs, the use of rotary tablet presses can improve production efficiency and reduce production costs.

- Scientific research experiments: In scientific research experiments, the rotary tablet press also plays an important role. Scientific researchers can use rotary tablet presses to make experimental tablets or conduct research and development of new drugs.

3.The importance of rotary tablet press

- Improve production efficiency: The rotary tablet press can produce tablets continuously and at high speed, greatly improving production efficiency. This is of great significance for meeting market demand and reducing production costs.

- Ensure drug quality: By adjusting the pressure, speed and other parameters of the tablet press, the hardness, thickness and other quality indicators of the tablets can be controlled, thereby ensuring the quality and efficacy of the drugs.

- High flexibility: The rotary tablet press can adapt to various types of drugs and production needs, and has high flexibility. Whether you are a large pharmaceutical company or a small pharmaceutical factory, you can adjust the parameters of the tablet press to meet your production needs.

- Easy to automate and integrate: Modern rotary tablet presses are usually equipped with advanced control systems and automation technology, which can achieve fully automated production, reduce manual intervention, and improve production efficiency and quality stability. In addition, the rotary tablet press can also be integrated with other production equipment to form a complete production line, further improving production efficiency and quality control capabilities.

In general, rotary tablet presses are widely used in pharmaceuticals and other industries, and are of great significance for improving production efficiency, ensuring drug quality, and reducing production costs. With the advancement of technology and the development of the pharmaceutical industry, we can expect more innovations and applications of rotary tablet presses in the future.