Solution

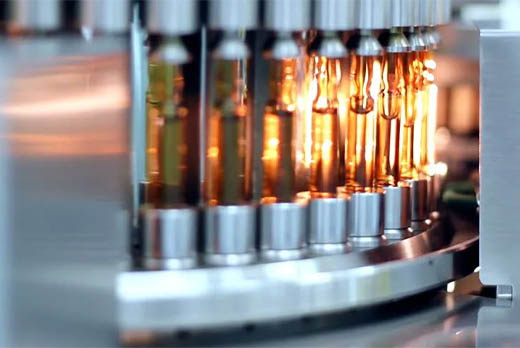

The light inspection machine is a kind of pharmaceutical machinery that inspects medicines in order to ensure the safety of people's medicines and prevent medicine accidents. It is the testing equipment after the glass bottle is filled with liquid. The light inspection machine is composed of a light inspection box, a light inspection table, a light inspection instrument, and a computer display screen.

Light inspection machine is mainly used for product inspection in medicine, alcohol, beverage and other industries. From the perspective of the type of milk bottle tested, the lamp tester mainly tests freeze-dried products such as ampoules, vials, and oral liquids. Due to the unstable factors of the traditional manual optical inspection machine, in order to enhance the international competitiveness of my country's pharmaceutical companies, the automatic optical inspection machine has become one of the indispensable inspection machinery for pharmaceutical machinery companies. Now, the automatic light inspection machine replaces the function of the manual light inspection machine, which not only improves the detection efficiency, but also improves the accuracy and stability of the detection. It is proposed to use the computer data of the tested product to judge various problems.

According to the principle of machine vision, the optical inspection machine uses a camera to capture the serial images of the medicinal liquor on the production line. After the image is transmitted to the computer, the computer uses a software algorithm to determine whether there are visible foreign bodies and impurities in the medicinal liquor. If so, the computer issues instructions to sort out defective products from the conveyor belt through PLC control. If the product is qualified, start the next process.

First of all, product feeding: check whether the bottle body has stains, whether the product has insufficient vacuum due to poor sealing or other factors, whether the bottle cap has no rubber stoppers or plastic caps, etc., and check whether there are foreign objects in the bottle: glass chips, fibers, hair, black Block, white block, color block and other insoluble matter, quantity and static foreign matter

Secondly, appearance inspection: head-shaped defects, such as pull tail, flat head, oblique head, carbonization, bottle mouth crack, bubble head, etc.

Finally, through the cooperation of a variety of detection methods, the light inspection machine can effectively eliminate foreign objects and sealing abnormalities. Some pharmaceutical companies have different requirements, and the detection function of the light detector can also be increased according to these different requirements.